Rotary Dryer Machine is a pivotal industrial equipment used for the purpose of removing moisture content from materials. It operates on a simple yet efficient mechanism involving rotating the material to be dried in a drum or cylinder, which is concurrently subjected to a stream of hot air.

This process effectively dries the material by evaporation. Rotary dryers are versatile and can handle a wide array of materials, including ores, fertilizers, chemicals, biomass, and more, making them indispensable in various industrial sectors.

Uses of Rotary Dryer Machines

Rotary dryers are employed in numerous applications due to their robustness and adaptability. Key uses include:

- Agricultural Industry: Drying of grains, seeds, and fodder to prevent spoilage and prepare them for storage.

- Mining and Mineral Industry: Drying of ores and minerals for further processing.

- Chemical Industry: Drying chemicals before packaging to ensure product stability.

- Biomass and Energy: Preparing biomass for biofuel production by reducing moisture content.

Industry Analysis with Specific Data

The global demand for rotary dryer machines is on the rise, driven by the need for efficient drying solutions across industries. The growth is particularly noted in the biomass energy sector, where the production of biofuels necessitates the drying of raw materials to improve combustion efficiency and energy yield.

According to market research, the adoption of advanced drying solutions like rotary dryers in the biomass sector could enhance energy output by up to 15%.

Classification and Working Principle

Rotary dryers can be classified into direct and indirect types, based on how heat is applied to the drying material.

- Direct Rotary Dryers: Directly expose the material to the hot gas within the drum, making them suitable for materials that can withstand higher temperatures.

- Indirect Rotary Dryers: Use a heat exchanger to heat the drum, drying the material without direct contact with the hot gas, ideal for heat-sensitive materials.

The working principle revolves around the drum rotating at a specific speed, allowing the material to tumble and mix for uniform drying as it is exposed to a stream of hot air or gas.

Process Flow

- Feeding: Materials are fed into the rotary dryer’s high end.

- Drying: As the drum rotates, materials are lifted up by flights and dispersed in hot air.

- Discharge: Dried materials exit from the lower end of the dryer.

Selecting the Right Rotary Dryer

Choosing the appropriate rotary dryer involves understanding the material properties, desired drying capacity, and specific industry requirements. For instance, a mineral processing operation might require a large, direct rotary dryer for efficient throughput, whereas a food processing plant may opt for a smaller, indirect dryer to preserve the quality of heat-sensitive products.

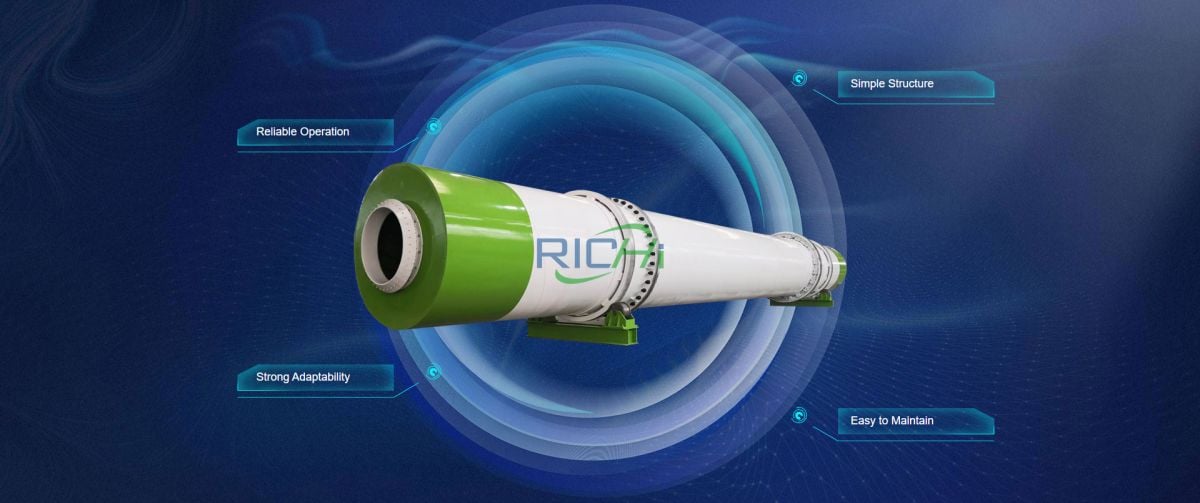

Choosing a Supplier: Highlighting Richi Machinery

Selecting a reliable supplier is critical. Richi Machinery, a prominent name in Henan, China, stands out for its extensive experience and capability to deliver customized solutions. They offer:

- Customized Pellet Production Lines: Tailoring rotary dryers to integrate seamlessly with pellet production lines according to the customer’s specific needs.

- Turnkey Projects: Specializing in comprehensive project management from design to full operational status.

- After-Sales Service: Ensuring long-term reliability and efficiency with ongoing support and maintenance.

Richi Machinery’s commitment to customization, quality, and service positions it as a leading choice for industrial drying solutions.

Practical Application Value

The implementation of a rotary dryer machine can significantly enhance operational efficiency, product quality, and environmental sustainability. By enabling precise moisture control, rotary dryers optimize the performance and energy efficiency of subsequent processing steps, thereby reducing operational costs and minimizing environmental impact.

FAQs About Rotary Dryer Machines

With proper maintenance, a rotary dryer can operate efficiently for over 20 years.

Generally, rotary dryers are designed to handle one material type at a time to ensure uniform drying conditions and product quality.

Optimizing the dryer’s operating parameters, such as drum speed and airflow, and integrating heat recovery systems can significantly improve energy efficiency.

Yes, when operated optimally, rotary dryers can reduce energy consumption and emissions, contributing to more sustainable production processes.

In summary, rotary dryer machines represent a fundamental technology in the efficient processing of a wide range of materials. With the expertise of suppliers like Richi Machinery, industries can leverage these sophisticated drying solutions to achieve higher productivity, improved product quality, and environmental sustainability, highlighting the substantial value they add to various production lines.